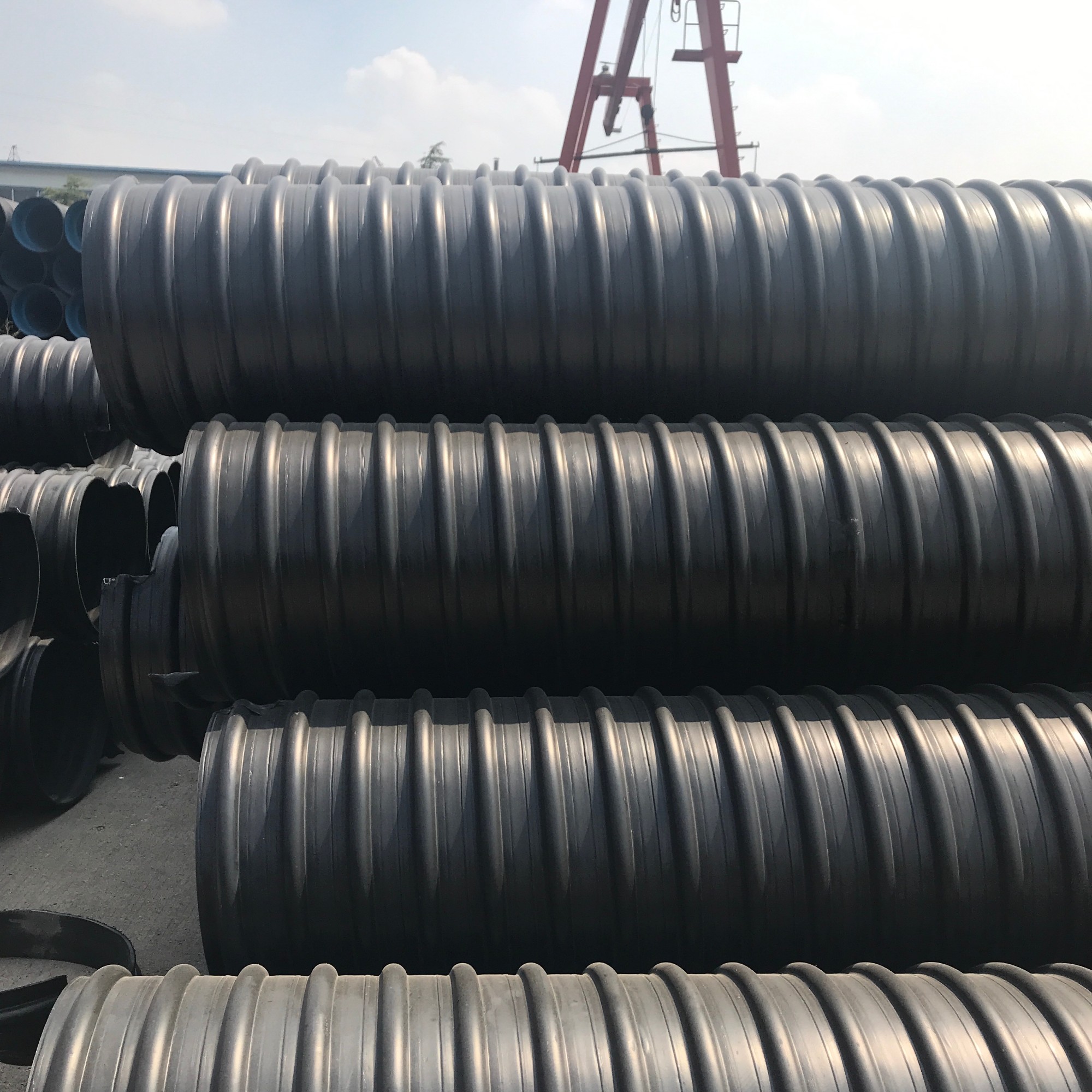

Steel Belt Reinforced Pipe

Executive standard: CJ/T270-2007 DN/OD: 200mm – 2600mm

Standard: CJ/T 270-2007

Materials: PE100

Color: Black, or black with yellow inside, or as client’s requirement.

Product Description

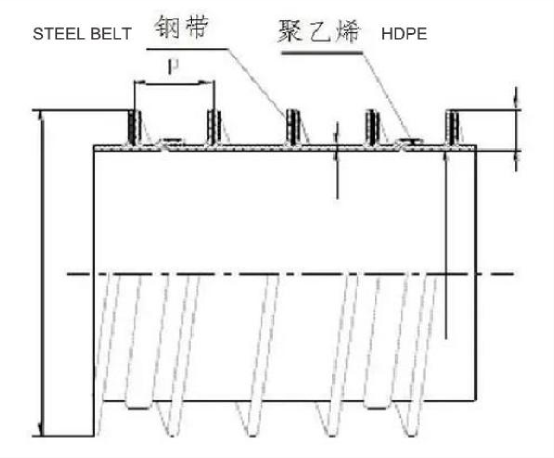

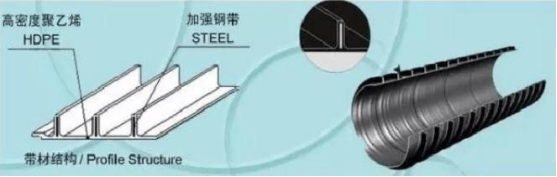

HDPE Steel Reinforced Spiral Drainage Pipe is reinforced through twisting steel-wire of high intensity into helix, made out of polyethylene of high intensity. The steel-wire frame is closely connected with the outer and inner polyethylene of high intensity adhesive resin layer which is a sort of great binding materials belonging to modified material of PE. It can be melt fully as one with PE in the heating conditions, while its polar bond has a strong adhesive property with the steel. Because of the adhesive resin, the pipe is more excellent in composition.

Specification

Nominal diameter | Minimum average inner diameter (mm) | Minimum steel strip thickness (mm) |

300 | 294 | 0.4 |

400 | 392 | 0.4 |

500 | 490 | 0.5 |

600 | 588 | 0.5 |

700 | 685 | 0.5 |

800 | 785 | 0.7 |

900 | 885 | 0.7 |

1000 | 985 | 0.7 |

1100 | 1085 | 0.7 |

1200 | 1185 | 0.7 |

1300 | 1285 | 1.0 |

1400 | 1385 | 1.0 |

1500 | 1485 | 1.0 |

1600 | 1585 | 1.0 |

1800 | 1785 | 1.0 |

2000 | 1985 | 1.0 |

2200 | 2185 | 1.2 |

2400 | 2385 | 1.2 |

Product Advantages

Steel belt reinforced polyethylene (PE) spiral corrugated pipe has the advantages that traditional metal pipe and concrete pipe are incomparable. It has the characteristics of acid and alkali corrosion resistance, water flow erosion resistance, strong anti-seismic and anti-freezing performance, high light weight and high strength (8-16KN/m2), strong anti-pressure and anti-settling performance, no leakage, convenient installation and long service life. The product can be used for soft soil quick-sand foundation, convenient connection, no leakage of joints, no secondary pollution, widely used in urban community sewage, municipal sewers, agricultural irrigation and other fields. The inner wall of the product is smooth, the friction is small, the water passing capacity is 40% larger than other pipes; corrosion-resistant, non-polluting, light weight, large-scale equipment is not required for transportation and installation, the engineering comprehensive cost is low, the service life is long, and the life under normal use can be Up to 50 years.

Pipe Details

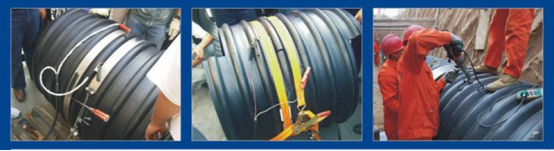

Connection Method

Metal Reinforced HDPE Corrugated Spiral Pipes Joining Method

Electrofusion Welding Method of HDPE Corrugated Spiral Pipes for Larger Diamater of Pipes

According to the diameter and length of each different, some will be merged with the pipe made of polyethylene tape coated with Electro fusion and it is implemented using copper wire welding machine. Centering on the inside with a piece of pipe to be made in fixing the merge process is ready to EFE sources. Belt use EF to clean the surface of the pipes will be welded later before proceeding with the winding process is performed and the ribs are fixed to the pipe and coupling place between them via a special apparatus.

After allowed to cool EF supply pipes. With regard to sealing the welded manually excruder from the pipe inner surface.Thus, the seal is eliminated danger. Another important note regarding the EF welding; The settings of the EF welding machine according to the pipe diameter.

Shrink Sleeve Method of HDPE Corrugated Spiral Pipes

This method is provided to seal the joints made by and used in the pipes is less than 1000 mm. Shrink sleeve is passed to the junction of two pipes and provides pipe coating is heated with the heater.

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Lori

Phone: +8618269993953

E-mail: lori@porainarpipe.com

Whatsapp:+8618269993953

Add: Room 1006,Building 15,zone B2,Bishui Yayuan,Liulin road,Yingzhou District,Anhui Province.