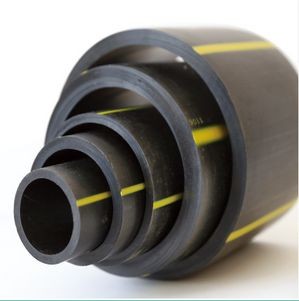

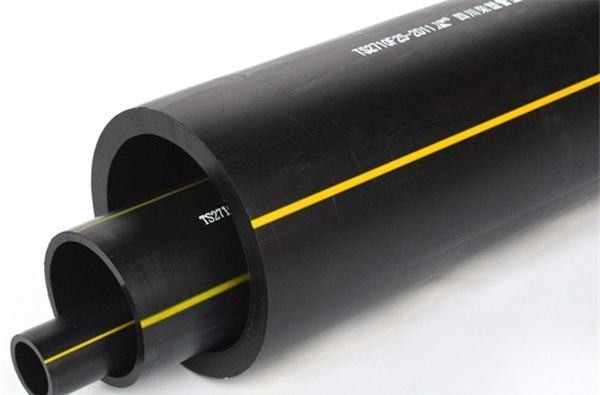

HDPE Gas Pipe

Product Description

The HDPE gas pipe takes the high quality polyethylene resin as its main raw material, according necessary anti-oxidant and anti-ultraviolet absorber auxiliaries and so on. It is one new product which is made of piling out. The HDPE gas pipe has the application of history of forty years around the world. It can be widely used in each kind of piping work, such as natural gas, liquefied petroleum gas, artificial gas etc.

Specification

STANDARD:GB/T15558.2-2003 | |||

PE100 gas pipe | |||

Nominal Outside Diameter(mm) | SDR17.6 | SDR11 | |

Wall Thickness (mm) | Wall Thickness (mm) | Weight(kg/m) | |

20 | 2.3 | 3.0 | 0.169 |

25 | 2.3 | 3.0 | 0.219 |

32 | 2.3 | 3.0 | 0.279 |

40 | 2.3 | 3.7 | 0.432 |

50 | 2.9 | 4.6 | 0.669 |

63 | 3.6 | 5.8 | 1.060 |

75 | 4.3 | 6.8 | 1.480 |

90 | 5.2 | 8.2 | 2.140 |

110 | 6.3 | 10.0 | 3.180 |

125 | 7.1 | 11.4 | 4.120 |

140 | 8.0 | 12.7 | 5.130 |

160 | 9.1 | 14.6 | 6.740 |

180 | 10.3 | 16.4 | 8.520 |

200 | 11.4 | 18.2 | 10.500 |

225 | 12.8 | 20.5 | 13.300 |

250 | 14.2 | 22.7 | 16.350 |

280 | 15.9 | 25.4 | 20.500 |

315 | 17.9 | 28.6 | 25.950 |

355 | 20.2 | 32.3 | 33.030 |

400 | 22.8 | 36.4 | 41.920 |

450 | 25.6 | 40.9 | 52.960 |

500 | 28.4 | 45.5 | 66.080 |

560 | 31.9 | 50.9 | 82.000 |

630 | 35.8 | 57.3 | 103.900 |

Product Performance

No. | Performance | Unit | Requirement | Test Parameter | ||

1 | Steady hydraulic pressure | h | Damage time≥100 | 20 ℃(hoop stress) | ||

PE80 9.0MPa | PE100 12.4MPa | |||||

Damage time≥165 | 80℃(hoop stress) | |||||

PE80 4.5MPa | PE100 5.4MPa | |||||

Damage time≥1000 | 80℃(hoop stress) | |||||

PE80 4.0MPa | PE100 5.0Mpa | |||||

2 | Elongation | % | ≥350 | |||

3 | Anti Climate | Hot stability. HS(165h/80℃) Elongation at break | E≥3.5GJ/㎡ | |||

4 | Resist fast crack propagation velocity(RPC) | |||||

Full Size(FS) Examination DN≥250mm Or S4 examination. It is applicable to all diameters | MPa | Critical pressure of full size Examination P≥1.5xMOP

Critical pressure of S4 examination P≥MOP/2.4-0.072 | 0℃ | |||

5 | Resistance to slow crack growth e>5mm | h | 165 | PE80, 80℃, 0.8MPa | ||

PE100, 80℃, 0.92MPa | ||||||

Product Feature

■ Reliable connection

Polyethylene piping systems are connected by electric thermal fusion, and the strength of the joint is higher than the strength of the pipe body.

■ Good low temperature impact resistance

The low-temperature temperature of polyethylene is extremely low, and it can be safely used in the temperature range of -60-60 ℃. During winter construction, due to the good impact resistance of the material, brittle cracking of the pipe will not occur.

■ Good resistance to stress cracking

HDPE has low notch sensitivity, high shear strength and excellent scratch resistance, and its environmental stress crack resistance is also very outstanding.

4. Aging resistance, long service life

Polyethylene pipes containing 2-2.5% of uniformly distributed carbon black can be stored outdoors or used for 50 years without being damaged by ultraviolet radiation.

■ Good flexibility

The flexibility of HDPE pipeline makes it easy to bend. In engineering, it can bypass the obstacle by changing the direction of the pipeline. In many occasions, the flexibility of the pipeline can reduce the amount of pipe fittings and reduce the installation cost.

■ Easy to carry

HDPE pipes are lighter than concrete pipes, galvanized pipes and steel pipes, it is easy to handle and install, and lower manpower and equipment requirements mean that the installation cost of the project is greatly reduced.

Product Application

■ Urban and rural drinking water pipelines.

■ Chemical liquid, chemical fiber, food, forestry, printing and dyeing, pharmaceutical, light industry, paper, metallurgical and other industries.

■ Agricultural irrigation pipelines.

■ Post and telecommunications lines, power line protection sleeves.

■ Mine mortar conveying pipeline.

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Lori

Phone: +8618269993953

E-mail: lori@porainarpipe.com

Whatsapp:+8618269993953

Add: Room 1006,Building 15,zone B2,Bishui Yayuan,Liulin road,Yingzhou District,Anhui Province.